From getting the right customization first time to winning more sales opportunities manufacturers get to offer higher customer satisfaction and generate more revenues.

With increasing customer involvement in furniture designs, manufacturers’ concerns of production complexity overpower the concerns in achieving quality benchmarks. Mass customization affects adversely on quality with frequent design revisions in a standardized design template.

But, today in ever evolving furniture design trends, surviving without offering a personal touch in is next to impossible. So what should the manufacturers do?

An interactive virtual platform of 3D visual product configurator promises a significant potential to achieve seamless design to order process. It can help manufacturers offer more design customization options and higher customer satisfaction to win more sales.

3D visual product configurators face head-on challenges that furniture mass customization throws up

Manufacturing a piece of wooden furniture can be a bit of a time-consuming process. And adding customization to it is even more complicated. Below are the five offerings of a 3D visual configurator that burns the quality hole and iterative design process that rises from adoption of mass customization.

1. Generates an interactive 3D model

Problem faced: When customers visit you, convincing them to make a bespoke product by explaining features in a standard furniture piece is difficult. It often results in strenuous customer association or losing the customer completely.

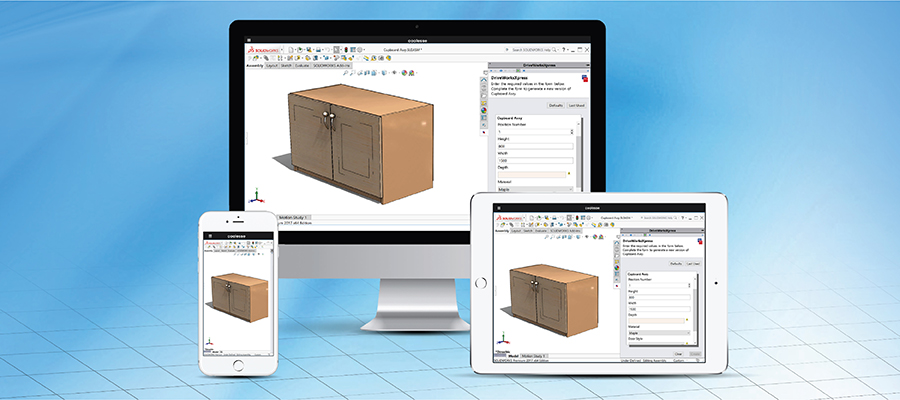

How visual configurator resolves it: With 3D visual configurator, you can project the customized features in a 3D environment which enhances design features explanation. It essentially offers a 360 degree view of the model and showcases drawings and spectacular textures to create visually appealing virtual products. This product in a virtual reality helps customers to easily reach a concrete conclusion, add suggestions, features etc.

Sometimes, advanced visual configurators equipped with AR/VR capabilities can also project the customized furniture item into an architectural plan of the customer’s house or office. Consider a customer asking to design a customized cupboard to make his/her house interior to look in a 3D view – Advanced visual configurators are capable of depicting that.

2. Faster and accurate sales quotation process

Problems faced: Your sales team without updated product knowledge is just as much of a threat to your business as it is when they aren’t able to reach out the customers at all. Lacking product feature knowledge, pricing, etc. portray an uncanny sales approach and tarnish your market value.

How visual configurator resolves it: By integrating product configurator with CAD, ERP, CRM etc. offers end-to-end design automation from sales to manufacturing even in case of modular furniture. This means that when an order is placed by the customer, the integrated configurator immediately generates 2D manufacturing drawings, part list and Bill of Material – BoM and alerts the shop floor to begin manufacturing.

The sales quotes are then automatically generated along with a comprehensive 3D model, instruction manual and installation guide for the assembling furniture and shared with the customer. These documents show every detail of a custom order including a cover letter and a BoM.

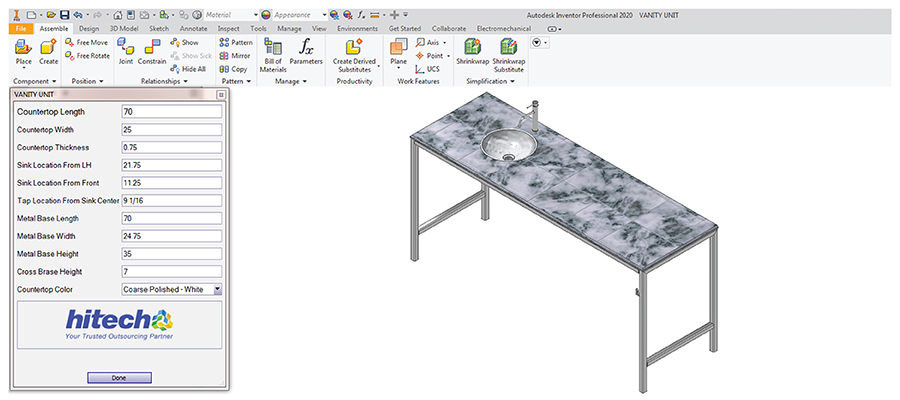

A US based Doors and vanity manufacturer faced challenges in managing mass arrival of drawing updates and customization. It increased their delivery times and errors in calculation of product prices. After deploying a configurator using Configurator 360 and Inventor iLogic they could achieve:

● Reduced delivery times of one hour from traditional 3-5 days

● 100% quality assurance and reduced design iterations

● Better customer experience and neutral file formats for easy communication

3. Seamless customization with ease in manufacturing

Problems faced: In the process of inclusion of customer’s precise specifications into the product aesthetics and designs, furniture designers often end up facing hassle during manufacturing. Moreover, the iterative process of design customization leads to increased engineering cycle resulting in higher pricing and even compromised quality at times.

How a visual configurator resolves it: Allowing the customers to give design specifications for products as personalized as furniture, you are, in a way, giving them the power to design their piece. It invites several design iterations before a design is approved and shop drawings are released for manufacturing.

As against this, visual configurators allow choosing options from product catalogue which are already tested, verified and have proofs of design concepts. It eliminates any non-permissible design values that are errored or technically inconsistent.

For example, while customizing a cabinet using a visual configurator, the customers can exactly how many shelves they need, the exact dimensions, material, locks, doors, hinges, veneer etc. And while changing the dimensions, the aspect ratio is maintained. Pre-defined logical rules won’t allow any non-permissible values and yet keep the customization very creative from a range of design options.

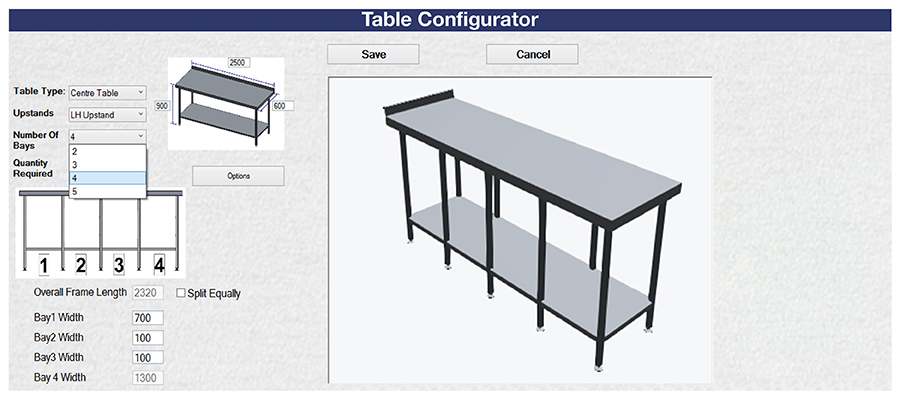

A retail food stall furniture manufacturer from the UK was venturing into mass customization of food preparation tables, but the manufacturer needed to develop an online configurator to speed up delivery orders by better communication.

They got a design database created and integrated with DriveWorks Live configurator to achieve:

● Better security with protected login credentials for customers

● Avoided hassle by sharing final DXF files and BOMs with shop floor

● Eliminated use of 3rd party database system which saved time

4. Enhanced customer satisfaction

Problems faced: With little visual details, making a purchase decision is a ghastly situation to put your customer into. But what’s even worse is the endless time lapse between making an order and actually receiving the finished furniture product.

How visual configurator resolves it: Visual configurator provides you with control options during customization of materials, dimensions and offers suggestions. With each change related to dimensions or geometry made in the master model, the configurator displays a real-time 3D model along with pricing quote. An interactive 3D environment can essentially terminate the unwanted back-and-forth interactions between the customer and sales reps.

A furniture manufacturer from the USA faced challenges in customizing the designs as per space availability and quoting the price accordingly. To resolve these complexities, they hired experts to integrate SolidWorks and DriveWorks to automate and accelerate several design tasks.

Impact:

● Reduce the lead time from 4 to 5 days to one day

● Design cycle was accelerated to 70 times faster

● Significant reduction in material scrap

How does a 3D visual configurator work?

Manufacturers can get a visual configurator developed and embed it on site or let their design engineers or remote sales team have access. When it is deployed on site you are opening gateways for customers to directly place orders online. In the latter case, you empower your design tech teams to speed up the design process or equip non-tech sales reps with latest product knowledge to enhance the sales process.

But in both the cases, you connect the engineering CAD systems and other business database systems with the configurator at backend. It provides necessary information for pricing and machining along with a rendered 3D visual of the product on the front end to the user.

How to implement a 3D visual product configurator

● Develop design database, master models and define logical rules

● Create user-forms for design inputs from customers/sales team

● Integrate the configurator with other database and deploy online

● Select components, define properties and ensure all the parameters are into the right fit

● Feed the additional information about customer’s communication details

● Integrated configurator will fetch data and calculate pricing, sales quote, manufacturing drawings, part list, installation guidelines and 3D model

One configurator for industry-wide transformation

Visual configurator not only offers the ability to configure in 3D but also transforms the processes from sales to manufacturing and establishes enterprise level automation. Importantly, it ensures that customers precisely focus on what they need without any deviation.

Since the 3D visual configurator performs several activities automatically, which were carried out manually in the past, their involvement could incur business process changes at times. A question that remains for you to answer is that the furniture industry transformation is on its way, are you transforming your practices?

Author Bio

Usha B. Trivedi is an engineer at Hitech CADD Services, a provider of computer-aided-design services. She frequently writes about mechanical and industrial equipment designs, furniture designs and the fabrication industry for manufacturers and engineering professionals. Follow her on LinkedIn.