Bouffant caps are used to keep stray hair in and water or other contaminants out. They are used in different industries like pharmaceuticals, fashion, food & beverage, to name a few. The caps look like a bag with an elastic opening that makes them fit perfectly around the hairline.

The caps are made from a lightweight (10gm) 100% virgin hydro-entangled (spunbond) polypropylene fabric. A latex-free elastic band is used to fit the cap to the user’s head without compromising comfort.

As people are more concerned about hygiene, these caps are up for great demand. That makes starting a bouffant cap making business seem profitable. One of the foremost things required to start up a business is an efficiently working bouffant cap machine.

In this post, we will discuss what a bouffant cap making machine is and how it helps in production.

A bouffant cap machine is a fully automatic & operator-friendly equipment that has made the production of bouffant caps super easy. It is known for its high-speed production without any errors.

The machine assists in the mass production of the caps and ensures that the final product is accurate and of good quality, as required by the clients. If you are looking for a machine that can be an advantage to your production unit, going for the mentioned machine can be one of your best decisions.

The machine automates the entire production process and requires minimal human intervention for delivering smooth and hassle-free manufacturing. Its efficiency can be experienced when you meet your project’s deadlines before time without compromising on the quality of the finished products. When you meet your orders on time, you have enough time to take on more projects that directly increase your revenue and boost your brand growth in the market.

Here are some performance characteristics of the machine:

- The machine uses non-woven material to produce quality caps and is backed with a robust body structure.

- Energy efficient with gear reduction motor.

- Equipped with PLC and frequency convertor for easier operation and production management.

- Can make caps of different sizes, like 16”, 18”, & 21”, along with PE shower caps.

Utilization

The caps made from the machine are used in the following industries:

- Catering and restaurant

- Food manufacturing co.

- Hotel industries (mainly as shower caps)

- Laboratories and Hospital

- Spa & Saloon

Working

Advanced technology is used in the making of the machine that makes it work efficiently. It has an in-build touch screen display connected with PLC for a hassle-free operation. The machine also has a frequency convertor to maintain a constant frequency for ensuring uniform stitching of the bouffant caps.

Moving on to the technical specifications, the efficiently functional machine can operate on a 220V 50Hz AC Power supply. It is designed economically so that it consumes a power of 4 KW for operations. The machine is engineered to perform at a speed of 125 Pcs/min, but it is advisable to maintain an optimum speed of 60-100 pcs/min.

Features:

Reliable performance

The machine is backed with state-of-the-art technology that makes them a reliable choice when it comes to producing high-quality bouffant caps. It is worth every penny of the money invested as help in bringing higher returns.

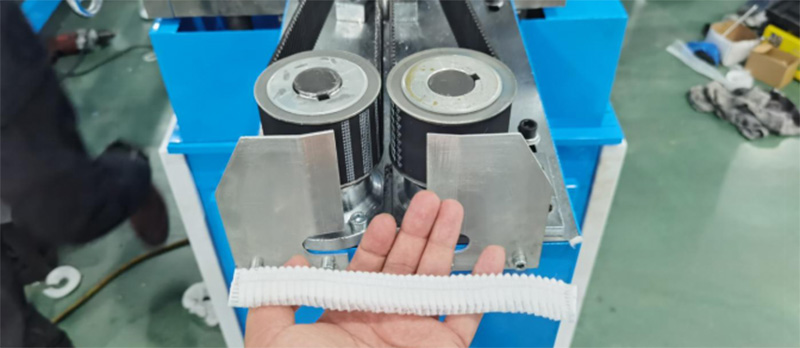

Robust body made from aluminum alloy

Aluminum is an efficient and effective material to create a robust body structure. The machine also has an aluminum alloy structure that adds to its durability, flexibility, light-weight, strength, corrosion resistance, and thermal efficiency.

Automatic tension control

The machine has the most required feature of automatic tension control that helps the operator to maintain a predetermined amount of stress on the given material and maintain the desired properties like appearance, form, and quality.

Cap’s size adjustable without changing any parts

The machine is known for its ability to produce different sizes of caps without the need for changing any parts. This helps in maintaining the pace of the production and meeting the different demands of clients with ease. Plus, the feature also ensures that the cap produced is of accurate size and the best quality.

Adjustable ultrasonic control

The machine has an adjustable ultrasonic control that ensures optimum stitching of caps from diagnostic ultrasound.

Reduce labor costs

With the points mentioned above, you must have developed an understanding of how automatically the machine can function. This leads to the conclusion that minimum labor is required for the operation and maintenance of the machine, resulting in less manufacturing costs and more profits.

Longer working life

The machine produces high-quality stitching without any direct contact with the surface. It works efficiently without causing any trouble and has the ability to function the same way for many more years to come.

BOTTOM LINES

A bouffant cap machine eases the process of producing high-quality caps at the least cost possible. We hope that the things mentioned above have given you a wide picture of what the machine is capable of doing and helping you grow as a business.