Packaging serves more purpose than just keeping your stuff together to get it from point A to point B; packaging can be of different types based on the product being packaged, the company selling that product, the buyers, budget, design, marketing strategy, etc. Given the fact that in the world of today the if your packaging is excellent, your products sell, merchandisers invest in finding out what attracts these buyers and what are the circumstances when a product fail due to poor packaging or only it failed to catch the eye of the buyer. Then there is a significant difference between plastic and paper packaging!

Plastic

More like the packaging of the past, merchandisers used plastic packaging because of its benefits, such as more extended durability, cheap packaging, customization options available, etc.

Paper

Paper is not a new packaging material, and it has far more benefits than plastic. When it comes to durability paper-based packaging scores right marks when it comes to cost-effectiveness paper scores much more marks but when it comes to other benefits, paper surely is more used around the packaging industry in the present than plastic was ever used.

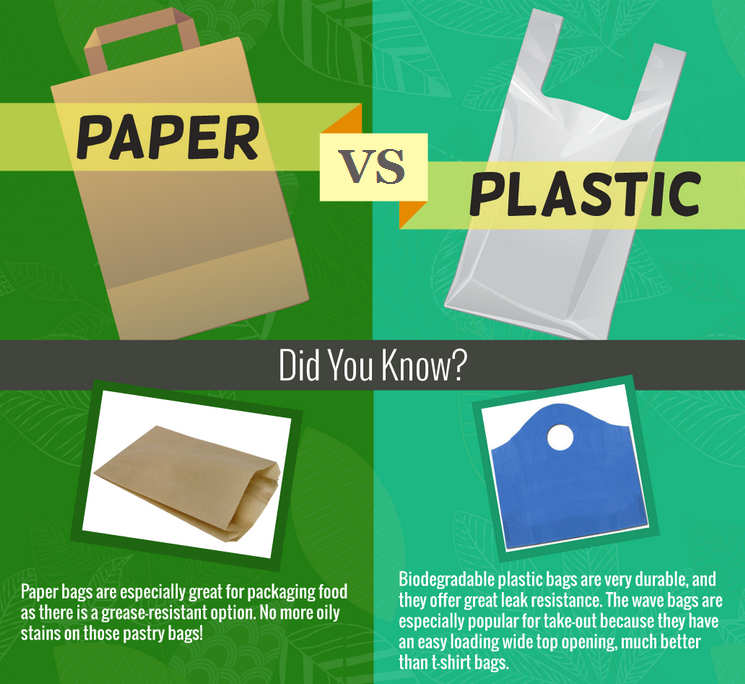

Plastic VS Paper

This debate is not old and keeps on coming to the surface whether plastic has more benefits or paper. The plastic packaging includes plastic and doesn’t have a wide range of types. Paper, on the other hand, has many kinds.

So let’s compare both materials one on one to check which is better:

• Paper is highly customizable, it can be folded, cut, pasted, thinned, and so on, paper is stamped, carved, embossed, laser cut, and it is easy to handle from technical point of view, plastic can’t take a lot of customization but if you want to go for extensive customization in vinyl anyways then it is cost you an arm and a leg!

•Paper is lightweight, and because the paper is thin, it makes it ideal for logistics and shipping industries that thrive on making things more comfortable for the merchandisers and work hard on reducing shipping cost. More weight means more loss, and if a huge box that is made of cardboard doesn’t weight that much, and it is only the weight of the product inside then, it doesn’t cost as much as it might have with any other material. Take plastic, on the other hand, to make a box of plastic you will have to use triple the resources, don’t forget that plastic may not be ideal for shipping because it melts in the heat and is not temperature resistant. So in that case plastic is not entirely suitable for shipping and paper-based packaging takes another mark.

•Plastic is not easy to handle

, one power breakdown and kilos of plastic in manufacturing goes to waste, is same the case with paper-based packaging? Nope. The production and customization of plastic are hazardous especially if you are a manufacturer yourself, there is more loss in plastic, and your target buyer will always be smaller brands that are not very concerned with environmental factors, but with paper your chances are high.

• Now let’s move on to a particular aspect, environment safe packaging. Plastic, if ends up in the sea, it does not dissolve, it ends up becoming feed of the life underwater and harms them. Plastic pollutes the sea, plastic in any form if burned causes pollution, the fumes are unhealthy, and there may be a lot of recycling happening, but it is not happening in the 3rd world countries. Paper is used so many times once a buyer buys the packaging! First of all, it dissolves, if not in days then in a long time but it does, it also is very safe for the environment because when burned it doesn’t release any toxic fumes to harm the environment. This a primary reason why the paper is more preferred than plastic will ever be.

Looking at a very general comparison between the two, plastic is out, and paper is in! Paper was only lagging behind when it wasn’t durable enough, but now it is glossed to make it long lasting. Cardboard and Kraft is already durable and tears resistant to a considerable extent even without glossing!