Falls are the no. 1 cause of work-related deaths in construction, representing 39.2% of construction deaths in the USA according to OSHA. However, we understand working at height can´t be avoided sometimes so the right fall protection equipment is necessary to save our life.

A safety harness is an important part of fall protection equipment. Selecting the right harness for working at height can mean a difference between life and death. In this article, we will explain the functions of different harnesses.

Types of Safety Harness

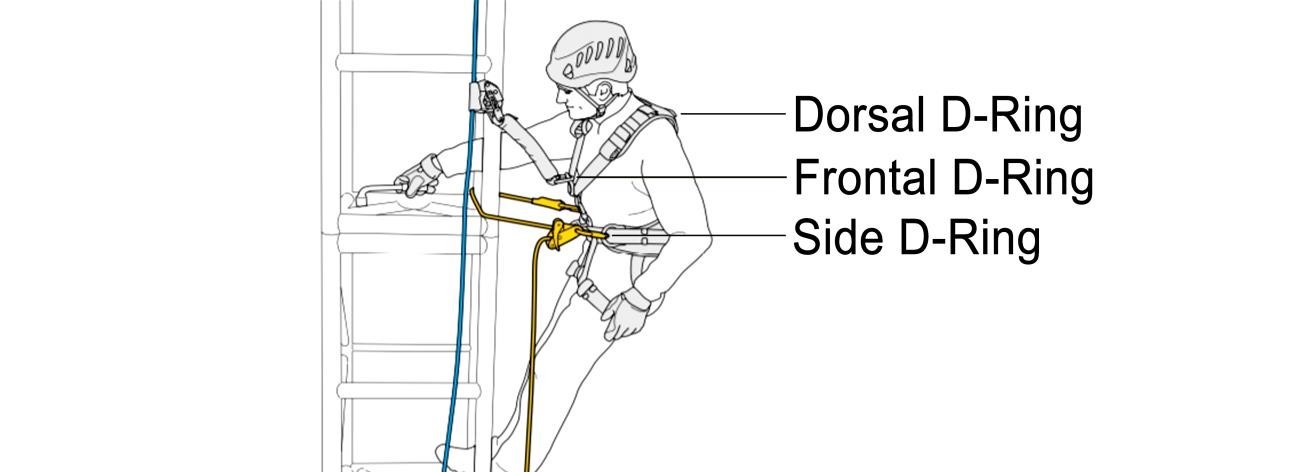

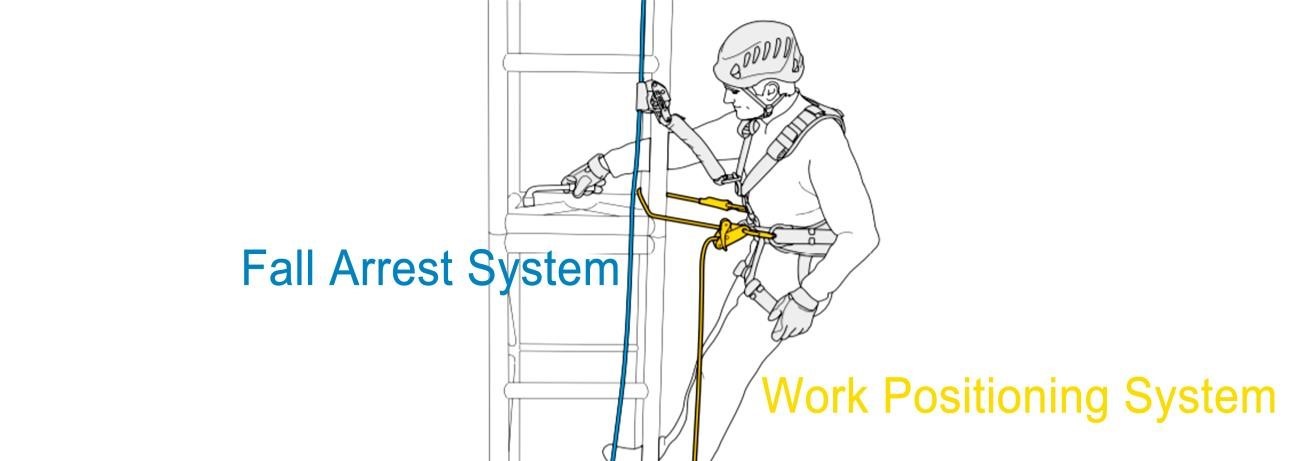

Harnesses are usually classified by functions, like fall arrest, ladder climbing, rescue, restraint and work positioning. Some feature one function or two and some can even perform all of them. In order to work properly, the fall protection systems like fall arrest and work positioning have to connect the right attachment points of a harness. For example, a work-positioning lanyard has to connect the work-positioning points or side D-rings of a harness.

When you are in the market for a safety harness for working at height, you have to understand different attachment points which are the unsung hero on a safety harness. Without them, your personal protective equipment is just a useless item.

2-Point Harness, 3-Point or More?

As mentioned, the attachment points on a harness are to attach to different systems for functions like fall arrest, work positioning, evacuation, and ladder climbing.

In the event of a fall, a full-body harness with attachment points equally distributes the forces of the fall throughout the whole body. This, in turn, protects vulnerable body parts like the groin, abdomen, and neck against serious injuries.

Connecting to the wrong points does not only fail to perform the activities but also costs you your life.

1-Point Harness

It is also commonly used for fall restraint. In a Fall Restraint System, however, the worker is restrained from reaching a fall hazard so a fall will not occur. The fall restraint lanyard acts as a leash, preventing the worker from reaching the leading edge.

The single-point harness is suitable for horizontal uses and the work which length adjustments of the rope are not required. This can be an ideal harness for working on the roof when the workspace is obstacle-free, e.g. burning roofing shingles.

2-Point Harness

Both attachment points are permitted for fall arrest. The frontal D-

ring is commonly used for fall arrest on fixed ladder climbing systems* to prevent the user from falling further. In the Recuse or confined space use, they can be the applicable D-ring connections. Please read carefully the manufacturer´s user manual before use.

Some 2-Point Harnesses on the market are incorporated with extra features to enhance product functionality e.g. with Hi-Vis Gilet, and with Life Jacket.

*When it comes to climbing uses, it can be easily confused with Work Positioning. But, they are not the same. More will be discussed next.

3-Point Harness

delicate tasks with both hands while maintaining stability. Imagine you are ascending a ladder and may want to stop and work mid-span to do some work, this is the situation you need a work positioning harness. A work positioning system should not be the sole means of protection while working at height. Work positioning equipment must be combined with an appropriate backup Fall Arrest system while working at height.

Go back to the last section, the frontal D-ring used for fall arrest on fixed ladder climbing systems seems similar to a work-positioning form but it is not designed to secure you on the ladder for hand-free tasks.

4-Point and 5-Point Harness

Safety Harness Inspection

Now, you can be able to choose the right harness for working at height. The next important thing is harness inspection!

This year, a construction worker fell 30 feet from a scaffold in Fort Lauderdale and sustained life threatening injuries. He was wearing a harness when he fell. Therefore, equipment failure is a possibility. It leads to this chapter – INSPECTION. According to OSHA and ANSI, your safety gears should be inspected before each use and every 6 months by a competent person. A full-body harness exposed to a fall arrest should be removed from service and replaced.

‘’OSHA 1926.502(d)(21): Personal fall arrest systems shall be inspected prior to each use for wear, damage and other deterioration and defective components shall be removed from service.’’ ‘’ANSI A10.32-2012: All fall protection equipment shall be inspected at least every six months after initial service by a competent person.’’

Download our Full Body Harness Inspection Checklist from the link above to carry out a regular inspection for your gear!

Author Bio: I am Iky Tai, an experienced SEO copy writer who loves writing. I have been working in industrial safety sector for years and sharing the updated news, safety rules and working tips with industry peers. I am now working in MTN SHOP that carries a wide range of industrial rigging products, fall protection equipment, etc. Whether you are climbing a tree or a tower; working in the warehouse, on the construction site, or on your sense of adventure – MTN SHOP is always here to make sure you’re ready for the trek ahead.