The Pneumatic Cylinder Manufacturers of India are producing different types of this piece of equipment to meet the requirement of all sectors. You can find different types like a single-acting cylinder, rotary air cylinder, double-acting cylinder, telescoping cylinder, and rodless cylinder. Recently, the industrialists prefer to use this as they run the noise-free operation as they don’t have to store the liquid. Another advantage of this cylinder is that it does not pollute the air and surrounding as this air-based equipment is quite clean and environment-friendly.

The uses of Pneumatic cylinder:

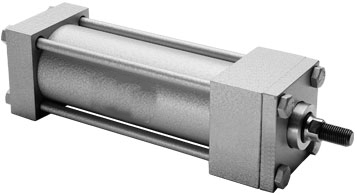

Equipment like the pneumatic actuator consists of a pneumatic cylinder, valves, and piston. The Pneumatic Cylinder Manufacturers dedicatedly work for industries like oil refining and chemical factories. For an electric motor, the pneumatic drill is also gaining popularity. There are many other types of equipment that has the cylinder as the part and those have been hugely used in different manufacturing units like air compressors, air brakes, pressure sensor, pneumatic bladder, and pressure regulator.

How to shop for the Pneumatic Cylinder?

Sometimes people may feel that shopping for the pneumatic cylinder is an easy, quick and unproblematic task when you look that from outside. However, there are so many things that one will understand only he will go to the shop where all are distorted. As selecting the pneumatic cylinder has a huge impact on your business decision, you just can’t take risk of not choosing the best one. When you will know the things you need to be considered while selecting the cylinder, you will land up in the right one for sure.

When you will invest in this equipment, you have to make sure; it does not only work perfectly in present but also will continue to provide the same service in the future as well. So, before you buy, gather all the required information so that you will make the right decision. If you have purchased the same in the past, then you must have the idea of how things would turn up.

These products are cost-effective which are ideal for the application of the slurries or the liquids containing a significant amount of sustaining solids. They are sealed by using one or more flexible elements like rubber tubes that become pinched to turn off the flow.

The working principle of the pneumatic cylinder is quite easy and pretty convenient to work with. The gas stored in the vessel has potential energy that will eventually convert into kinetic energy under forced compression. The air will force the piston in order to expand and thus shift to larger force significantly. The operation of the cylinder is based on the force created by the pressurized gas in the vessel.