Injection molding is the most well-known technique used to make enormous quantities of indistinguishable things from plastics. Most polymers can be utilized simultaneously, and items delivered by plastic injection molding manufacturing incorporate container covers, plastic brushes, little household items and even vehicle entryway boards.

Basically, the plastic injection molding manufacturing procedure includes taking care of plastic polymers in a pelletized structure through a container into a chamber. When adequate liquid plastic material has gathered toward the finish of the chamber the screw goes about as an unclogged and the material is infused into a shape, generally made of metal. Molds are throughly intended to mirror the specific prerequisites of the item being created. At long last, the plastic hardens into a shape that has adjusted to the state of the form. Once cooled somewhat, some of the time an automated arm is utilized to evacuate the shaped segments however it is more normal for the newly made things to drop out of the form into a chute prompting an assortment compartment.

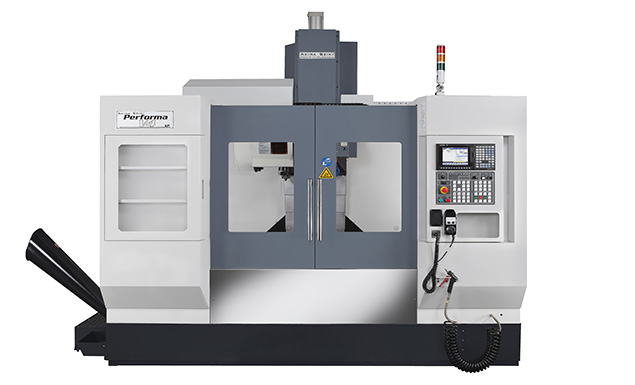

An injection molding machine is utilized to build plastic items by the injection molding procedure nitty gritty above. There are two fundamental parts to the machines, the injection unit and the clasping unit. In most of injection molding machines the shape is affixed in the flat position, yet forms can likewise be fitted in the vertical situation at times permitting gravity to help the procedure. Molds are most regularly attached to the machine by manual clips utilizing screws yet can likewise be secured utilizing water driven or attractive cinches which both take into consideration quicker tool changes.

Injection molding machines are appraised by weight and Shot weight which communicates the measure of clasping power that the machine can apply to keep the shape shut during the procedure and the most extreme load of article that can be shaped. However, machines are fundamentally grouped by the kind of driving frameworks they utilize specifically water driven, mechanical, electrical or half and half. Water powered machines are generally transcendent in many pieces of the world except for Japan and were the main alternative accessible until 1983. However, generally utilized they tend not to be as exact as other machine types. Industrial injection molding machines will in general be more solid than different sorts.

Electric injection molding machines decline working expenses by diminishing energy utilization and furthermore address a portion of the environmental concerns around these machines. They are more costly than different sorts yet are calmer, quicker and more exact.

Plastic Injection Molding manufacturing Company: What qualities make a good company?

Plastic injection molding manufacturing is a mainstream producing process where parts are made through the injection of plastic into molds. The procedure includes the taking care of the plastic into a warmed barrel, blending it up, and constraining it into the form hole. It is then left to cool and solidify. Pick your plastic molding Services organization cautiously to guarantee you get an incentive for cash. You have to have characteristics of a decent organization readily available in case you are to settle on an educated decision.

The organization should take measures to guarantee there are no imperfections. In case there are such imperfections, it needs to be the organization’s obligation to fix them, including by making new parts. The absolute most basic accessories surrenders are rankling, consume marks/dieseling, shading streaks, de-overlay, streak/burrs, installed debases, and stream marks. Others are flying, weld/sew lines, polymer debasement, sink marks, short shot, spread imprints, tackiness, voids, and distorting/contorting.

The resistances need to be worthy. Adequate industry principles are ±0.500 for thermoplastics. Specific applications need higher resilience levels. Many organizations focus around top notch standard and accuracy just, however tasteful appearance is additionally significant.

Go for an organization that has practical experience in plastic injection molding manufacturing. Such an organization will have the limit including the gear, devices, and labor to work superbly. The organization should offer extensive help, which means it needs to do everything from structuring, improvement, tooling, the real injection molding, get together, extra printing, and testing.

Assembly needs to be done to such an extent that there is no danger of parts falling to pieces even with the utilization of weight. The absolute best assembly methods are embedding marking, hot firearm sticking, kitting, electrical sub-get together, and sonic welding. In-house testing is significant as it guarantees that the parts conveyed will work. Probably the most significant sorts of tests are progression tests, air rot tests, pressure tests, and electrical tests.

Digitalization is significant as it implies less human mistake and therefore more noteworthy quality levels and lower costs. Go for an organization that utilizations Advanced Product Quality Planning, Effect Analysis and Failure Mode, Production Planning Approval Process, Operational Qualification, Corrective Action Preventive Action, Performance Qualification, Installation Qualification, and Statistical Process Control in the assembling procedure.

The Novel Mould organization offer an assortment of plastics with the goal that you pick what best suits you. Other than the conventional ease item polymers that are utilized in plastic injection molding manufacturing like cellulose acetic acid derivation butyrate, polyvinyl-chloride and polypropylene you need to likewise have the option to browse advanced polymers like polyarylamide, isoplast and polye theretherketone for pro applications and building polymers like acrylonitrile butadiene styrene and polyethlene terephthalate for high mechanical quality applications.

A decent plastic injection molding organization like Novel Mould is one that has been around for a very long while since this is demonstrative of its validity and unwavering quality. The organization need to have a background marked by fulfilling severe time constraints. Learn more