The lost wax investment casting process refers to a procedure where casting of a replica sculpture can be done from a sculpture that is original. Known by a variety of names such as investment casting, precision casting and “cire perdue” (French), the oldest artifacts made from the lost-wax casting process date back to 4500-3500 BC in Israel. Other than that, artifacts have also been found in other parts of the world. Although the procedure has been modified according to recent times, and varies according to foundries, the traditional methods are still preferred and the steps are standardized.

- What’s the process behind lost-wax casting?

The casts are made from a copy of the original model, which could be made clay that is oil or wax-based. The moulds have outer and inner moulds, into which molten wax is poured to create an even coating over the inner surface. The outer mould is made from plastic or fiberglass, while the inner mould is made out of polyurethane rubber, latex, and silicone. Moulds mostly consist of two pieces along with a shim containing keys, which are required to reconstruct the original sculpt. After the poured-in wax cools down and hardens, the mould attains the preferred thickness.

The wax model is then removed from the mould, which may be used for making multiple models. A heat-resistant mixture is then poured into the mould to blend out any defects, and the shell is secured with many layers of the plaster. Other molded pieces are now attached to the main body. The model is inverted and baked in a kiln, which dries out the plaster and the leftover wax runs out.

After removing remnant moisture, the shell is then packed with sand and molten metal is poured into it. After it has cooled down, the shell and the core are removed which reveals the original casting. The metal is now “chased” to blend out flaws, and the casting now looks identical to the original model. The final casting is filed down and finishing touches are added as needed.

- What are the other uses of lost wax investment casting process?

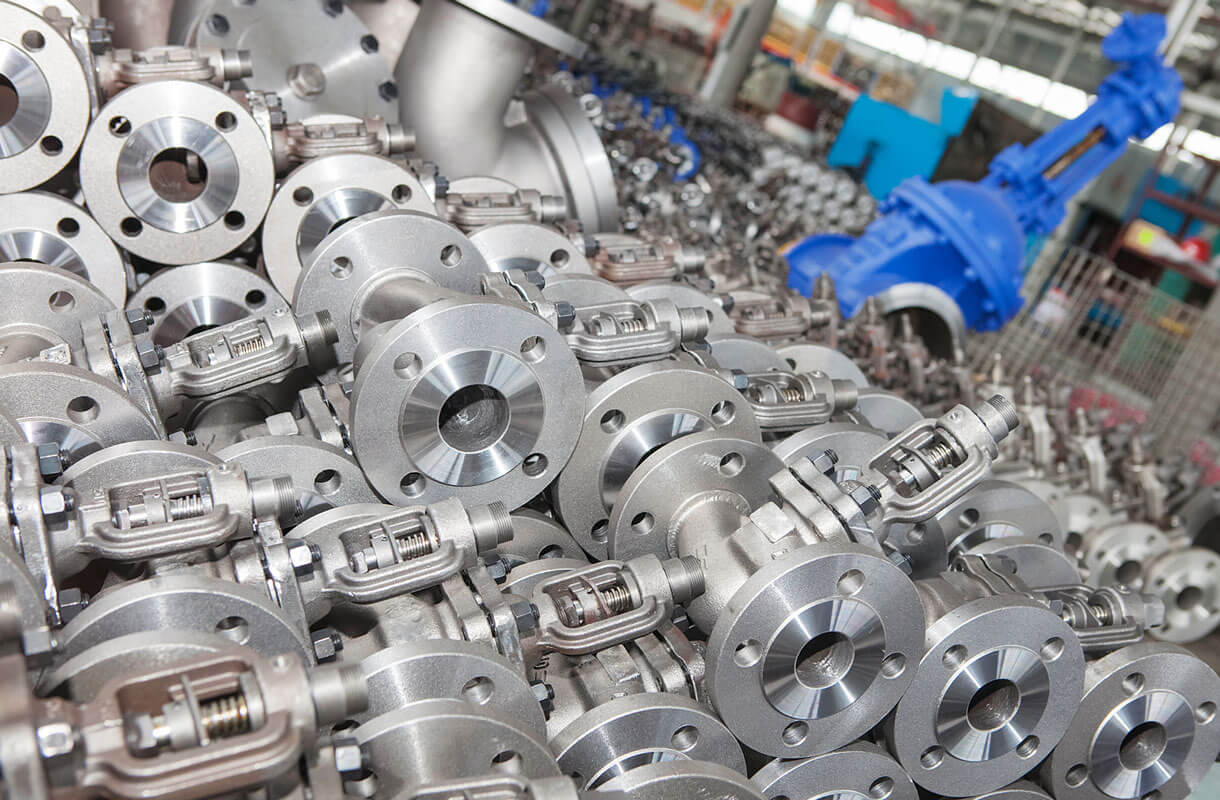

The lost-wax casting process has been used by foundry-men and artists to make intricate sculptures, ornaments and automobiles for centuries. Apart from this, the process is also popular for making casting jewelry, brooches, buckles and other small parts needed in various industries. Lost-wax casting can also be seen in textile use, where the wax and textiles are replaced by metal when casting. Due to fabric reinforcement, the model is thinner which reduces the amount of metal used in the mould.

- What are the advantages of the lost-wax casting process?

Despite modern ways of casting, foundry-men and artists still prefer the traditional methods of casting. Some of the advantages include –

- The lost-wax casting process can be used on any material that can melt burn and evaporate to leave behind a mould cavity.

- The duplicate model will reproduce even minute details of the original sculpture.

- Allows for unique shapes of casting that would be impossible in other methods.

Therefore, the lost wax investment casting process is a seasoned method for the reproduction of various objects. However, the procedure does have its disadvantages such as the initial cost, need for large machinery and the particularity of holes in the mould. Therefore, it is important to look for expertise, design, performance and cost to get the best quality at the best price.