With a wide range of industries, different production techniques emerge. All industries need parts and prototypes all the time. Take a look at the medical industry, automotive industry, aerospace, you name it! One thing we can agree on is that they all need quality and high precision parts custom by CNC machining.

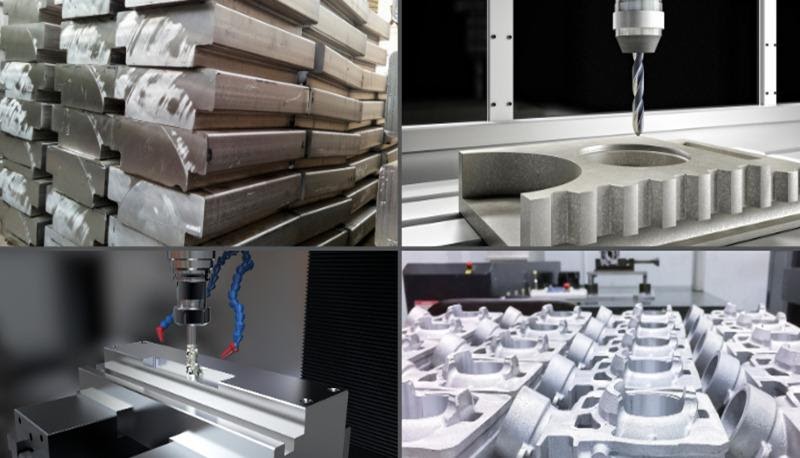

Custom CNC Machining for part and prototype production

Computer Numerical Control (CNC) machining proves to be reliable in quality part production. The process is ideal for the production of parts with intricate geometries. The process involves feeding a Computer-Aided Diagram (CAD) file into a CNC center and the rest is automatic. With little human intervention, you will reduce cases of human error. Thus CNC machining guarantees you accuracy and high precision parts with complex geometries.

In our daily lives, we come across a lot of CNC machined equipment without knowing. Here are some industries that rely on CNC machining for part production.

Custom CNC machining for the Medical Industry

When it comes to human life, there is no room for error. CNC machining gives you customized medical prototyping services. We have several surgical instruments and medical apparatus produced through custom CNC machining. Medical instruments need high precision and excellent repeatability. You cannot afford to joke around performance-critical medical components.

Materials used

• Metallic medical components come from materials like Steel, Titanium, Brass, and Zinc.

• Plastic can be, PVC, Nylon, and PEEK.

CNC machining processes

It includes: CNC Milling, Turning, Drilling, CNC Threading, and Surface grinding.

Examples of custom CNC machined medical components;

a) Anatomical models, Ultrasonic equipment, MRI devices, X-ray devices, and Medical carts among others.

b) Surgical scissors, Biopsy tubes, and saws for bone surgery come from CNC machines.

c) Dental implants and prosthetics are also made by CNC machining.

Did you know that Titanium is the most biocompatible metal? For this reason, we use it in making prosthetic limbs. Titanium remains inert in the human body. This means that it is not affected by body fluids. The metal is also strong, flexible, and compatible with bone growth.

What benefits does the medical industry enjoy by working with custom CNC machining services?

a) Custom CNC machining is relatively affordable. This is evident since they need large volumes of similar parts. It is easier to produce large volumes of parts with excellent repeatability using CNC machines.

b) You have a wide range of materials to choose from. This in turn guarantees you quality. CNC machines can work with a wide range of metals, plastics, and acrylics.

c) High accuracy. Most of the process is automated. This means that there is little human intervention. The programs running the process are well-vetted, tested, and do not have errors. You can rest assured of quality and accuracy.

d) Strong capacity. CNC machining centers can work with large volumes of parts. Machines are not prone to fatigue, unlike humans. The process can run all around the clock.

Custom CNC Machining for the Automotive Industries

In one way or another cars have been in existence since the nineteenth century. Over the years, the process of manufacturing has changed. Vehicles are no longer hand-assembled. Robots and auto components have proven worthy of the task.

Custom CNC machining has played a major role in the transition. Seeing as we are looking forward to autonomous cars and increased light-weighting for fuel-efficiency we will need CNC machining even more. When the CAD file is loaded the computer sends commands to a motorized tool. It can be a mill, drill, or lathe. The material is cut into the required shape and geometry. It is much better than ordinary machining. Automotive firms are saving a lot of money and time by filling up their workshops with CNC machines. CNC machining can meet the need for high precision and accuracy even with complex geometries.

What Car Parts Are CNC Machined?

CNC machined car parts;

a) Engine

There are several components of a car’s combustion engine made through machining. These are; engine cylinder block, Cylinder heads, and other parts enclosing the cylinder block

b) Lighting

Polymethyl methacrylate (PMMA) and other acrylics are machined to car headlights and interior lighting.

c) Other parts: exhaust parts, suspension components, valve retainers among others.

Advantages of using custom CNC machining services in the automotive industry

a) The use of CAD files in CNC machining gives room for easy alteration of the design when needed.

b) Custom CNC machining offers fast production. It is all about speed.

c) For cost-efficiency, automotive firms take their orders in large volumes. They need a production process with high repeatability. CNC machines have repeatability thanks to automation.

d) Custom CNC machining services guarantee you high accuracy and precision.

Materials used;

The planes and jets undergo extreme conditions while in use. They need high strength and temperature-grade materials. Examples are:

a) Aluminum

b) Titanium

c) Carbon steel

d) Nickel

e) Steel

CNC machined parts and components for the aerospace industry

f) Plane engine

g) Hydraulic manifolds

h) Landing gear

i) Fuel bodies

Benefits Accrued by the Aerospace Industry for Working with Custom CNC Machining Services

a) The 5 axis machining allows different tooling to work on one piece along the X, Y, and Z-axis simultaneously. This removes the need to reconfigure the part.

b) Aluminum and titanium are much lighter than steel and are all machined. Light weighting for fuel-efficiency is a major aspect a manufacturer looks at in the aerospace sector.

c) CNC machines can work with tight tolerances and achieve high levels of precision

d) With state-of-the-art software and inspection processes, custom CNC machining can give quality end-use components and prototypes.

Conclusion

Custom CNC machining has and will continue to play a role in the medical, automotive, and aerospace industries. The industries are saving money and time by investing in custom CNC machining services. Soon, we will have better and advanced production techniques. Change is inevitable. The scope of innovation is wide. With technology, we will continue to perfect the art of CNC machining for better results.

Apart from the three industries we have talked about, there are others like;

Commercial and consumer products

Electronics

Oil and energy industry