Every day new items are introducing in the market. Slight changes brought in the item style perk up the need for a new box as well. The use of cardboard has always been a great way around the wrapping needs of the product. There are many ways to style this material in the hopes of making it look versatile. An average looking item looks beautiful in a well-designed box. Corrugation boxes are a type of packaging that is made out of cardboard. Many renowned companies are using custom corrugated boxes for their brand and product marketing.

A simple cardboard box is reshaped and modernized to cater to the latest needs of the wrapping industry. The plain and smooth surface of the paper sheets gives a beautiful look to the box, but over the years, the concept of beautification has changed dramatically. Not only new methods of creating these items are introduced, but also customization of such boxes is found its way in the packaging industry.

How to Corrugate a Box?

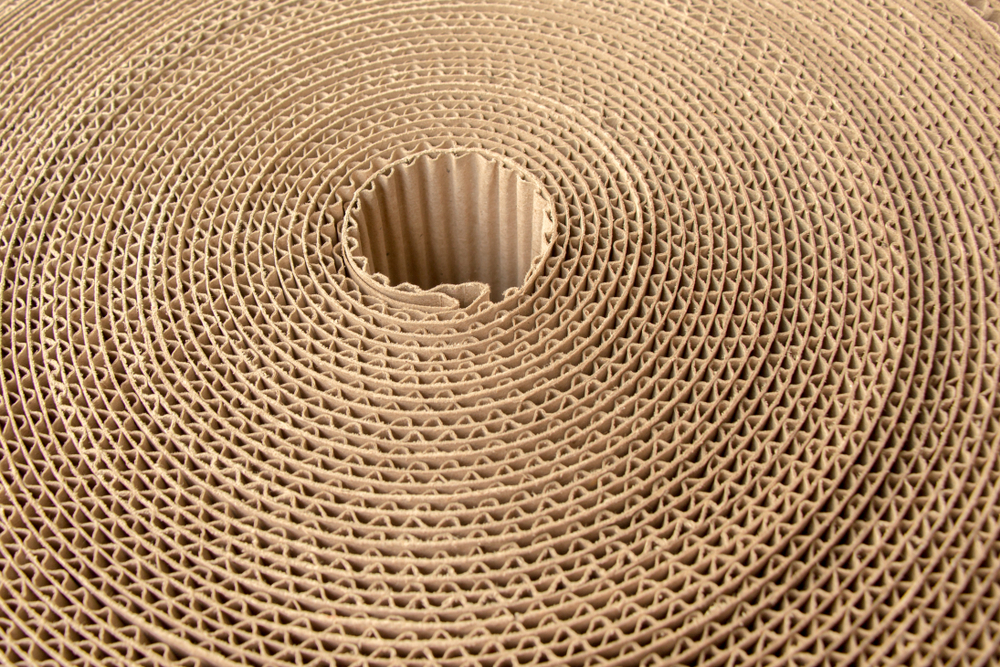

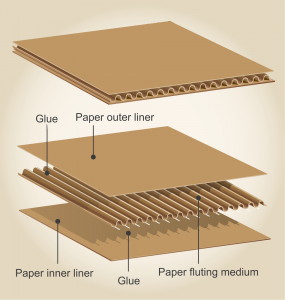

Corrugation is a simple process that, when implemented, changes the outlook of the box. As much as the process is simple, it is interesting, nonetheless. Simple cardboard is single-walled and light in weight. The wall of these containers has three layers in it. Both outer layers have smooth paper while they sandwich a single layer of arch patterned cardboard in between.

This curved cardboard sheet is a flute that is mostly made out of eco-friendly or recycled cardboard. This provides a subtle cushioning to the item, which is encased inside the box, to prevent minor accidents from damaging the goods. The wave-like pattern of this layer gives space for air to flow through the dips. This creates a bouncy effect every time a bump or nudge comes along the way.

Custom corrugated boxes can have two walls inside them. It is for items that are more fragile and delicate than the others; it is important to take care of them accordingly — this option of creating the box as per requirement peaks the interest of manufacturing companies.

A double-walled container is much sturdier and safer than a simple cardboard carton or a single-walled package. As the name suggests, there are double layers of fluting in between the walls of the sheet. This makes up a total of 5 layers that are ever ready to protect the items packaged from any harm.

Why Does Corrugation Help?

There are multiple reasons for using corrugation while creating a package. Marketers verify the above-mentioned reasons. There pros and cons are evident, but as the positive points almost negate the negative one, companies still use this style of packaging for their products.

1. The ability to create custom printed corrugated boxes in any form and pattern spikes the interest of companies. If companies know the chance to beautify a box for their marketing purpose then they will surely make it happen. Printing out the relevant and important details on the box while personalizing it to look unique, kicks the sales up a notch.

2. Cardboard can withstand the weight and pressure of many materials but we still need a much stronger base to wrap heavy weighted materials. Custom corrugated plastic boxes come with two layers of plastic engulfing the third one. This corrugation makes the box withstand the harsh realities of retail even better.

3. Sending out items is an issue for the shipment and production companies. Clients expect the merchandise to reach at their doorstep without facing any damage. Custom corrugated shipping boxes are particularly designed from regular boxes. So they can bear tears, scratches, and other situations that can wear out the box.

4. Each packed product has different dimensions so they need a different size of boxes. The change in the properties of the merchandise requires custom size corrugated boxes to hold them. Out of shape boxes are not attractive, and people tend to mistrust the companies which do not take care of this issue. If the box is larger than the need, extra money requires at every step. Whereas, a smaller packaging is unable to store the product altogether.

5. The custom Corrugated Boxes by The Custom Boxes is one of the most cost-effective packaging styles available for the retailer and franchise owners.

The cost of production, as well as designing, is lower than the other box styles. Using recycled cardboard lessens the price on the production of fluting. A corrugated wrapping is and recyclable, which adds to the attractiveness of the box.