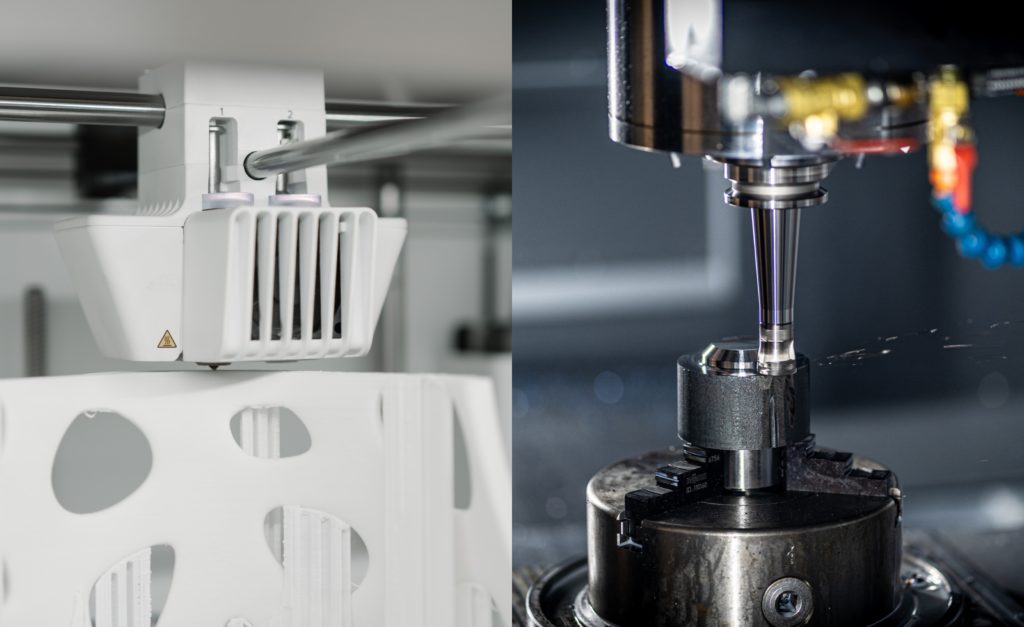

With the rapid advancement of Industry 4.0 implementation, companies are shifting to more efficient manufacturing options. Both CNC machining and 3d printing are high-end manufacturing methods that are efficient, cost-effective, and performance-driven. However, many businesses get confused when it comes to picking up the correct technique for their manufacturing.

Both the technologies come with unique characteristics that help you meet your manufacturing requirements with perfection. So, let’s deep dive into both methods to pick the best fit for your business on this note.

What is CNC Manufacturing?

CNC machining is a subtractive metal fabrication process in which the engineers operate the machine through computer codes. The codes instruct the machinery every move in which the cutting head will span around the cutting surface. It’s a subtractive method in which the material is removed from the block to form the required shape. From spindle speed to RPMs to cutting accuracy, everything is pre-defined through the computer program.

CNC machines are fully automated, and they require digital files with instructions to execute the cutting operations. The machining process requires several tools to manufacture certain parts. In this process, engineers can also prepare digital tool libraries that will interface with physical machines to adjust several settings automatically.

What is 3D Printing Technology?

Unlike CNC, 3d printing or additive manufacturing is an ‘additive’ method in which the objects are formed by printing the design in a layered fashion. 3D printing is a popular rapid prototyping technology in which the designers prepare 3D CAD models. Once the CAD file is sliced through slicing software, the layers are sent to the 3d printer, and the machine starts printing the object layer by layer.

3D printing technology brings in superior personalization that lets engineers produce complex geometries in a much-streamlined manner. In addition, compared to other traditional manufacturing methods, 3d printing is more agile and on-demand.

Similarities Between 3D Printing and CNC Machining

There are several similarities between additive manufacturing and 3d printing that you need to know before choosing one technology.

Design Models

The first similarity among these two manufacturing technologies is that both require digital models to produce the object. Therefore, engineers can easily prepare 3d models of design and start manufacturing them without conducting any additional processes.

Suitable for Prototyping

Prototyping technology and the complete concept is booming across multiple industries, and both methods can produce high-quality prototypes. Whether it’s small-batch production or large-batch production, both technologies are highly accurate, precise, and cost-effective. Both procedures help companies save substantial time and resources.

Compatibility

Compatibility is not an issue whether you opt for 3d printing or the CNC machining method. Both methods support STL and OBJ file types that are the commonly-used file types in digital manufacturing. And the best thing is that you will also find several open-source design files that you can use for free.

On-Demand Manufacturing

As the world moves towards fast-paced development, both production technologies are ideal for on-demand complex manufacturing. Compared to other traditional processes, these two methods are highly convenient and easy to operate. Moreover, as these processes are fully automated, there is minimum scope for human intervention and errors.

Main Differences Between 3D Printing and CNC Machining

The core working mechanisms of both the production methods are different, and several aspects are unique and different. Below are some common differences between 3d printing and CNC machining that you need to know.

Material Wastage

When it comes to using materials effectively, 3d printing is more efficient than CNC machining. As 3D printing service is an additive process, the material wastage is minimum. On the other side, as the CNC machine carves the parts out from a metal sheet, the wastage is higher.

Parts Size

CNC machine service can produce objects in various sizes — from crafting tiny parts to manufacturing large-size bulk parts, this method can handle most manufacturing jobs. On the other hand, you can only 3d print parts that are as big as the printing bed. To manufacture big-sized parts, you need to break down the design, print smaller components, and then assemble them.

Manufacturing Speed

For mass-producing, CNC machining can offer a faster turn-around time compared to 3d printing. It is because CNC machining has an assembly line compared to a single printing bed on 3d printing. As 3d printing makes the entire object from scratch to finish, it makes it less relevant for large-scale production.

Product Quality

As a CNC machine has higher heat tolerance, it can produce objects with a smoother surface finish. On the other hand, the quality of 3d printing varies over several factors like material type, type of 3d printing technology, design structure, and more.