The distinctive component of electrical contactors and relays is that they work under a similar guideline. In the most straightforward terms, both the referenced devices are solenoid changes charged by the power to change and deal with the electrical burden. Their construction is practically similar, which further backs numerous similarities in their functioning standard. Anyway, how do contactors and relays work, and how are they made? Both these devices include a top lodging with a lot of contacts.

These contacts are generally open; however, they may likewise be found in a closed state. In contrast to the top lodging, the bottom part of the housing in both these devices includes an excellent magnet and coil that proceeds to keep up with and protect tertiary accessories.

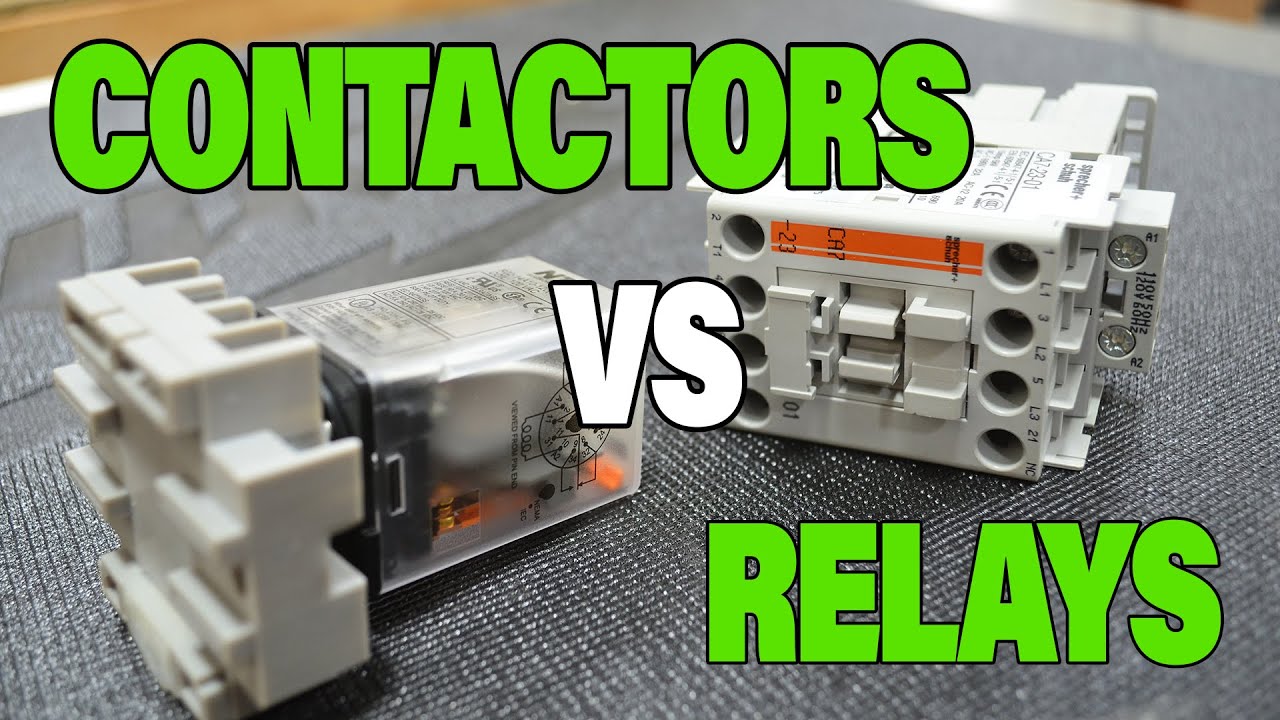

Key Difference Between Relay and Contactor

Since now you have clear know-how of the functioning guideline of Relay and Contactor, you may consider the critical difference in these devices. The essential difference between the two gadgets is the electrical flow rating that they are worked to maintain. Since Contactors are used to dealing with high voltage and current electrical loads, they will generally have specific distinctive differences from the standard relay. To better comprehend the contrast between the two gadgets, survey the accompanying component definitions that sum up the gadget’s job and reason.

– Function

Control relay is best characterized as an item that guarantees that every one of the contacts in a particular circuit can be effectively operated in any event when the conditions change in something very similar or comparable circuits.

Then again, contactors are devices intended to interfere with a current electrical circuit in an ordinary environment.

– Size

The key difference in both the products is in their size. When contrasted with contactors, control relays have a minuscule size. Then, due to this little limit, control relays have less burden than contactors.

– Electrical Load and Circuit Range

While contactors are most appropriate for carrying electrical burdens higher than 10A, control relays can carry electrical loads up to 10A. That is likewise why you would ordinarily find control relay systems working in single-stage circuit types, most overwhelmingly the control circuits. However, contractors can effectively deal with the three-stage electrical burden.

Kind of Contacts

One more relevant distinction among relays and contactors lies in the devices’ helper contacts. While you will find three electrical power contacts for specific additional built-in contacts in a contactor, a standard control relay will hold back two NO or NC sort of electrical contacts. Once more, while you will find control relays with both open and close contacts, your average contactor is custom-fitted to work just with genuine contacts. In contrast to relays, they work on Form A contacts.

System Appraisals

As referenced before, the last and the most significant contrasts between relay and contactor the two devices lie in their system appraisals and voltage control limit. While ordinary transfers have a 250 V rating, a contactor will, for the most part, have a rating of 1000 V or higher. It is essential to note that the two devices’ most remarkable differences are in their size and underlying elements. Relays are a lot more modest than contactors, and that is why their capacity, voltage, and limit are regularly restricted when you contrast them with a contactor. Since the devices are practically unique, you can’t use them reciprocally.