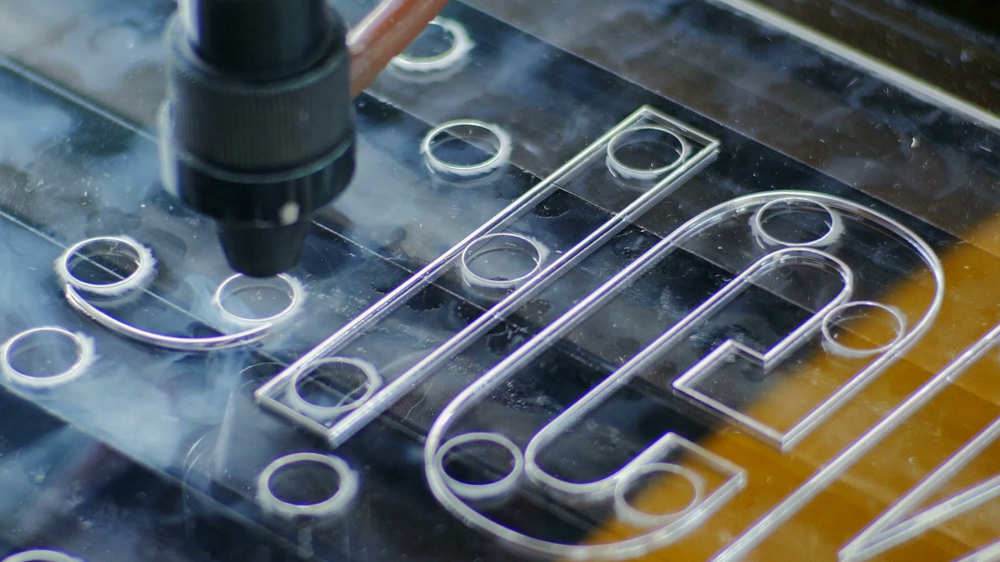

Most of the companies now rely on 3D laser cutting rather than the other conventional processes for the benefits that it provides.

- The most significant benefit of it is that it will allow you to work on flat surfaces and larger parts. Even if you have to assemble the different laser cut parts for a large 3D object, it will still prove to be a beneficial and cost-effective solution over 3D printing or any other processes.

- Another significant benefit of 3D laser cutting is that it will provide really high precision cutting if you choose the dimensions properly. This means you will have minimal to no wastage of material, adding to the price effectiveness of 3D laser cutting.

- You will be able to work on different materials to produce varied custom items. You will be able to design visiting cards or boxes, furniture or decorations, irrespective of the type of material used for the manufacturing of it.

Lastly and most importantly, this process will help you to make the most of the available design possibilities regardless of its complexities involved. You can create more exceptional custom-made parts by using laser engraving to add more details and to personalize the products even more.

Tips for Laser Cutting

In order to get the best possible results in 3D laser cutting and most accurate parts, keep in mind these following tips that will help you to make the most out of this unique technology.

- Start by choosing the right material as that is very important for accuracy. You may use a solid, translucent or flexible material, but you must know the different properties of different materials to see whether or not it matches with the project and your expectations. You will need to select a material that will be most adapted to your work in terms of color, thickness and design guidelines.

- You must also be very specific and careful when it comes to the spacing between the two parts so that it is equal to the thickness of the material used. This will ensure that you avoid errors while cutting and breaking the part. It will make the final object more resistant.

Also, make sure that you space the letters well so that it is clear and not too small. This will make the laser engraving more readable. Always pay close attention to the maximum and minimum dimension requirements during tube laser cutting from Naimor.

Common Mistakes To Avoid

In 3D laser cutting, it is easy to make mistakes and there are a few common ones that you should avoid for sure. Since this is an exceptionally high-tech machine process, there is a fair bit of intimidation factor.

- One of the two most common mistakes made is missing tool resolution or kerf width. Most users consider these to be infinitely narrow cut lines. They are certainly not. The range is typically between 30 microns and 300 microns which ideally is much narrower than other processes. Considering the laser power, you must set up the optical measurements in accordance with the process.

- Another common mistake is called tabbing which involves supporting the smaller parts using micro-joints. Lasers typically use high-pressure gas which requires the objects to be held properly at a place either by their own weight if they are thicker or by these joints if they are smaller.

These micro-joints are very small often 0.2 to 0.4 mm wide and therefore are easy to break during post processing.

In short, it can be said that provided you use the laser cutter properly and follow the right process, nothing can beat the functionality and accuracy of 3D laser cutting, making it so favored in the industry.