To transport gases and liquids as well as some solids, complex piping systems are a mandatory requirement. The requirement can be anywhere, in an aluminum smelting plant, a power plant for oil and gas industrial units, and many other facilities where the transportation of process liquids is inevitable for the functioning of the unit.

Now, pipe fabrication is all about manufacturing the required dimensions of pipes and piping components using appropriate materials with high tensile and shear strengths. Fabrication includes forging elbows, connectors, tee fittings, reducers, forging flanges, etc.

All about the Piping Fabrication and Installation

Pipe fabrication plays a significant role in the social infrastructure of any country. The industrial facilities, the institutional facilities, and the commercial facilities altogether will heavily rely on the expertise of these pipe fabrication services.

As a result, examining and evaluating the piping measurements and dimensions is an important part of the testing process before the pipeline begins transporting liquids and gases.

Mechanical design checking and correction are also done before operations, and process control measures are also tested in the laboratories.

So, to begin with, the fabrication part, there are different types of operations in the Piping Fabrication and Installation projects, like welding, beveling, cutting, bending, and some other pipe-forming operations.

Highly skilled craftsmen are used for these different jobs related to pipe fabrication and installation.

Quality Conformance

Dimensional accuracy to precision standards is a crucial requirement when it comes to pipe fabrication because hundreds of components need to be aligned during the assembly of a pipe network.

That is the reason comprehensive planning, operation scheduling, and supervised execution become paramount for any construction project where pipe fabrication is a necessity.

The criteria based on which all these preparations are done include time, budget, location, and design standards as required by the client.

Process of pipe fabrication

There are two methods of fabricating pipes. Depending upon the size of the pipes to be made and also the many other factors involved in the fabrication process, you can either choose to manufacture the pipe and its components in the workshop for production on the shop floor or at the job site.

The following list of factors will help you decide whether pipe fabrication can be done on the job site or in a workshop.

- The first factor will be the prevailing weather conditions in the particular locality.

- The second consideration will be the dimensions of the pipe and also the pipe’s material availability.

- Similarly, the availability of manpower and technical equipment on the site, as well as the accessibility of the required service crew and maintenance professionals, are also taken into consideration.

- Safety is the owner’s most important consideration when deciding whether the fabrication must be done on the job site.

- Other major considerations include welding facilities and the surrounding environment in terms of quality control requirements.

Some of the applications will be for the existing pipeline, and some other projects will be for fresh fabrication at a new site. All of these factors will influence the type of equipment, manpower, and other resources that can be used, as well as the location.

Steel Pipe Fabrication Installation services

Checking the components for accuracy and uniformity with relevant tests is the step before Steel Pipe Fabrication Installation. The spool drawings of the pipe fabrication requirements are used to accurately assess the feasibility of the transportation procedure even while moving the units from one location to another.

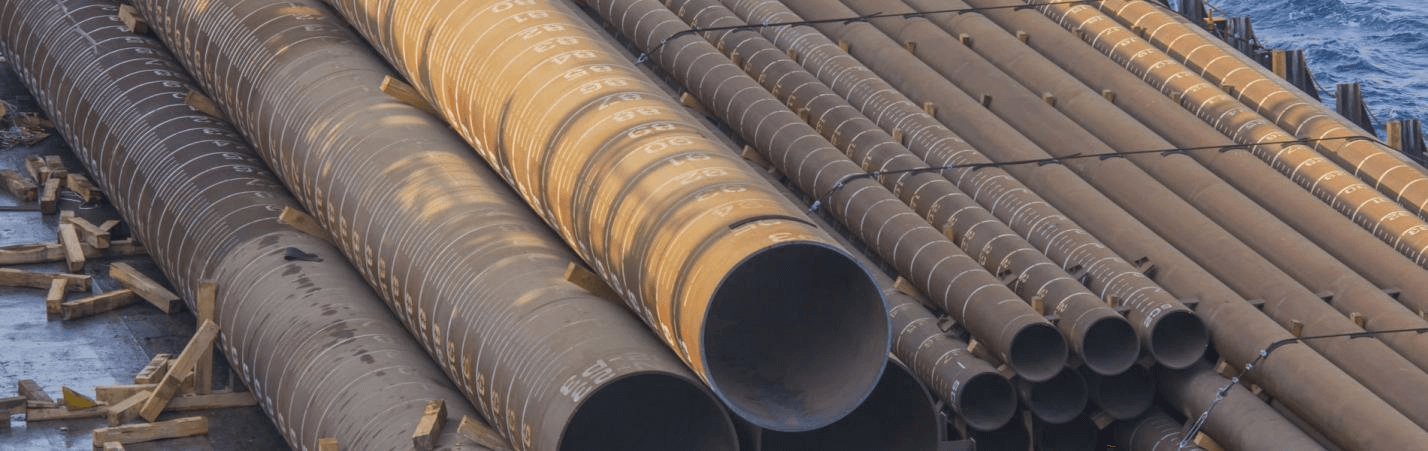

Even the sub-assemblies are robust enough to divide the biggest pipeline projects into smaller, easier-to-transport pieces so they can be transported from the workshop to the offshore site.

Workshop-based Piping Fabrication and Installation

Let us see the nuances involved in the affair where the pipe fabrication is done in the workshop, and then transportation is done from the workshop to the offshore location.

Dedicated workshop facilities are always available for pipe fabricators to manage projects of different sizes and capacities. The workshop will be constructed in such a way that there is no harm caused by the elements to the workshop workforce, equipment, or jobs in the process.

Specifications are an important part of a pipe fabrication project. All the drawings, the inspection procedures, and the testing techniques, as well as the regulatory standards and applicable codes, are available in the documentation. This is called the Piping Fabrication and Installation specification. This is the blueprint for all the fittings and pipes, as well as how they are made and installed by many trained artisans under the supervision of professional engineers and architects.

Steps involved in the Steel Pipe Fabrication Installation:

Marking and Tagging: Marking the pipes, joints, and important areas is the primary need. Marking is done as per the specification and standards. Tagging is done on the pipes, to mention the heat numbers. Paint or a stamp is used for this purpose. These tags are found in almost all the sections of the pipe so that the varied operators can understand the code.

Cutting: Cutting the pipes with precision is possible with the gas torches that these pros use. Also, plasma-cutting techniques are deployed in some cases. Depending on the material choices, they use saws, grinding machines, tools, and much more.

Finishing: Bevelling and fitting are final tasks executed following approved standards and specifications.

Welding: Planning is done before welding. This is to ensure that the seams are positioned in the right alignment per the final assembly specs.

Fitting and details marking: The fitting and detail marking processes are then completed, with welding details marked and inspection signatures adjacent to the joints. Aluminum tags are used to mention the spool numbers of the pipes. Paints are also used for the same purpose.

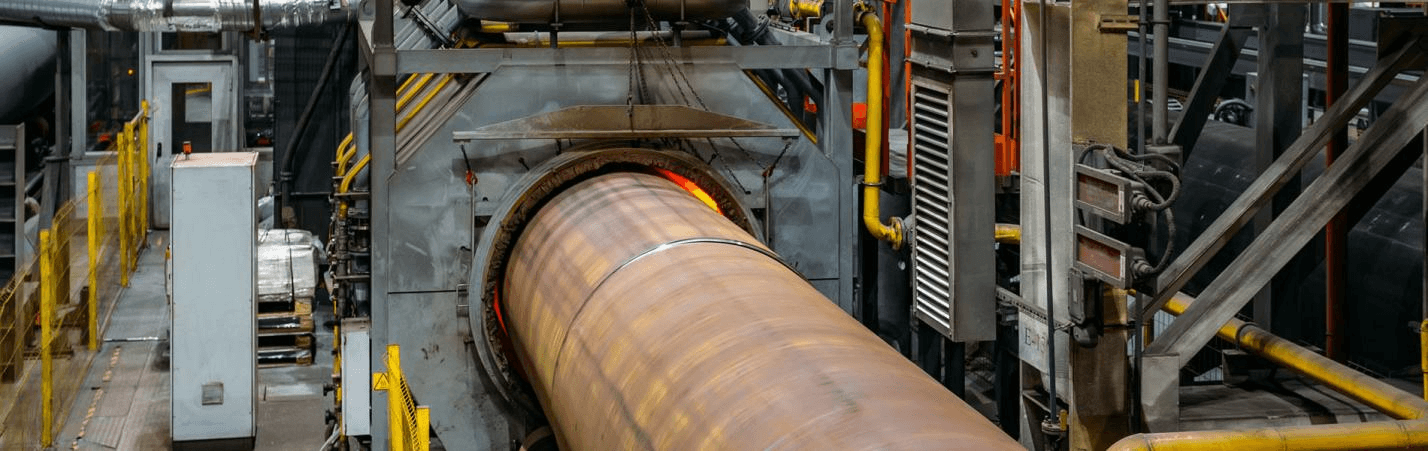

Heat treatment and safety in Steel Pipe Fabrication Installation: The pipes are then heat treated, and non-destructive testing techniques are used to determine the strength of the materials used in the fabrication. If the tests are not passed, the repair work is done accordingly. Sections that have passed must be painted.

A wide range of tools and equipment are used in the process, and the primary objective at all stages is to exercise caution to ensure all types of safety measures while using these resources. So, a dedicated pipe fabrication expert can always make a huge difference in providing quality Steel Pipe Fabrication Installation services. Get assistance from the professionals now.