What to consider while picking the correct casting cycle. Casting is one of the most established assembling procedures going back to 1838. While the essential casting cycle hasn’t changed a lot, the present machines are further developed and with upgrades in innovation, there are a few unique approaches to arrive at your final result or part as it were. Two normal and fundamentally the same as cycles are die casting and investment die casting.

Die Casting: Understand the Process

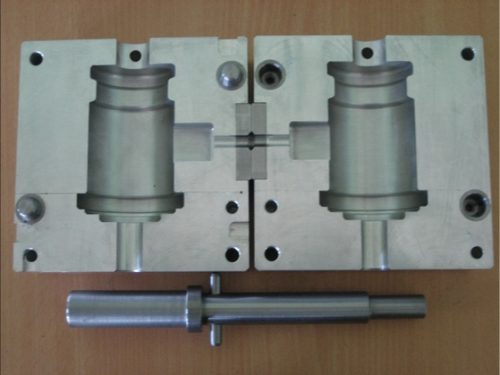

Basically, when die casting a section, in that case liquid metal is infused into a solidified steel die; At the point when the metal sets it is launched out from the device and the cycle is rehashed. The cycle shifts somewhat relying upon the material you pick see hot chamber and cold chamber die casting. The solidified steel shape is equipped for making somewhere in the range of 150K shots to over 1,000K shots before it would should be changed or even repaired.

Investment Casting: Understand the Process

Making a section utilizing the investment die casting or lost wax measure is regularly an additional tedious cycle where a wax model of your part is made and afterward consistently dunked into liquid ceramic. The ceramic solidifies and afterward the wax is dissolved out leaving you with an artistic form. Liquid metal is then filled the ceramic cavity where the wax used to be. When the metal hardens, the ceramic form is broken and eliminated leaving the metal casting. The form used to make the wax example can be utilized commonly anyway the ceramic shape is broken and disposed of with each part.

What is the ideal process to select from?

No two casting activities are the equivalent and with various tasks, there are various arrangements. Here are a couple of interesting points before you start your next task to assist you with picking which cycle is ideal for your segment.

Selection of Material:

Most die cast parts are produced using non-ferrous metals like zinc, magnesium and aluminum. Investment die casting is fit for casting cast those metals alongside ferrous metals, including tempered steel. In case you are hoping to utilize a non-ferrous material, the two cycles offer equivalent features. In any case, you are hoping to utilize hardened steels or copper amalgams; investment casting is the better alternative.

Yearly Volume:

When choosing which casting cycle to utilize, choose what your ideal compensation period is for the apparatus cost. The number of parts made versus the expense of the tooling to earn back the original investment. While investment casting tooling might be less expensive and reasonable for lower volume investments, die casting is ideal for bigger creation runs and high-volume investments.

Resistance:

With any casting cycle, resistance abilities are to a great extent affected by the state of the part and the kind of material utilized. The table beneath analyzes general straight resistances for traditional die casting and investment casting. The multi-slide die casting cycle is fit for holding significantly more tight resiliencies.

Duration of Process:

While investment casting and die casting both produce complex parts, the process durations contrast enormously. Customary investment casting is an ideal cycle that needs a considerable amount of work and long periods of work, while die casting can create 3 to 4 shots for every moment for ordinary die casting and as much as 45 shots for each moment with multi-slide die casting. A die cast part can generally be made without the bit of a human hand total automation.

Price:

Duration of process decides up to 60% of your last part cost so it is nothing unexpected here, that per part, investment casting by and large costs more than die casting. It’s profoundly manual cycles yield parts fundamentally the same as that of a die casting, however the process duration is any longer.

When casting in high volume, die casting is more practical than investment casting. In case you are casting just a couple of parts or require bigger size or hardened steel, investment casting might be the cheaper alternative.

While both investment die casting and die casting make leaves behind equivalent highlights, when very high-volume producing is wanted, the related expenses and longer process durations can make investment casting a appropriate alternative relying upon your requirements and cutoff times. It is ideal to talk with professionals from Novel Mould to figure out which casting cycle is most appropriate for your next investment contact our group today!