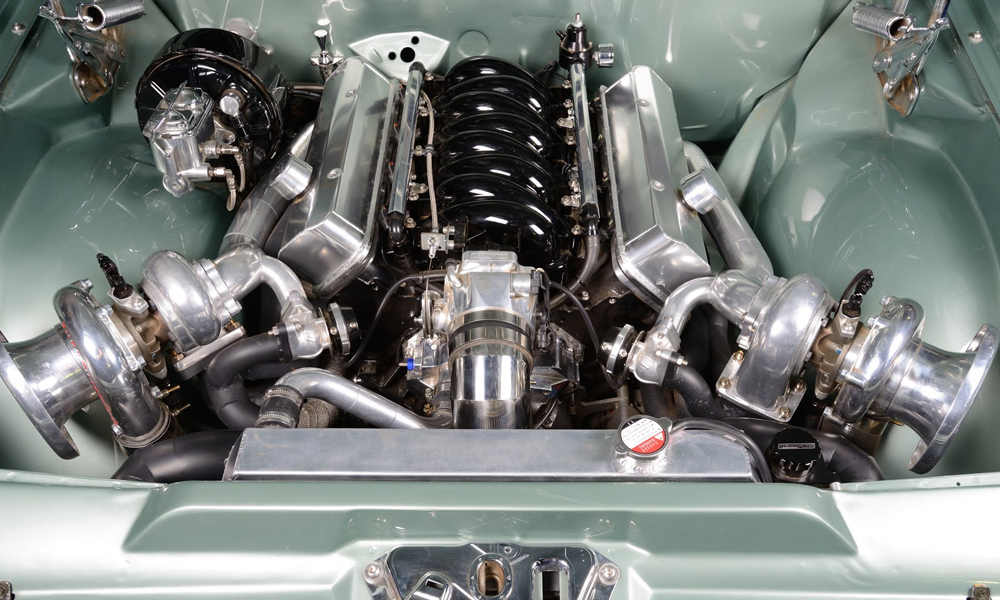

Evolution in engineering experiments and application make it possible to design and fabricate the model of Twin Turbo, which is not only working exactly for the motor vehicles, but also have the provision to protect the machines with qualitative functions. A 400 kilo watt turbo charger has the power of 650Nm with the rotational speed of 2000 rpm to 5500 rpm. It is available with CAPA mechanism. This deals with various properties like rapid acceleration, fuel economy, emission filtration, swift technology, torque graph different from single forced induction motor. The CAPA technology uses the latest technical terms and mechanisms to obtain the sustainable torque and optimum power with innovative cooling technology. This technique is introduced in maximum vehicles to achieve the efficient acceleration.

Twin Turbo Ls 1 operates with different kits to provide spin optimization. Those different kits are,

- Water or oil cooled turbo

- Goat intercooler

- HP gear facilities operated by oil pump

- Anodised fittings

- Pipes of silicon parts with T clamps

- Valve of 50 mm blow

- Water or oil feed lines

- Water or oil returns lines, etc.

Such motors are designed about to achieve the goat performance and also designed with affordable, complete, Twin Turbo, and bolt facility in Australia. If you are looking for more and more horse power with more spin and torque, you can go with the option of goat performance rather than forced induction. It provides the affordable package of required torque, obtaining by Twin Turbo Ls1 motor. The reasons behind the development of turbocharger for LS 1 mechanism are,

- Scavenger pump can make damage to the engine.

- Oil drains directly into sump.

- Heat is released by engine bay may create the poisonous effect in foot well.

- Turbocharger can resist the damage of vehicles.