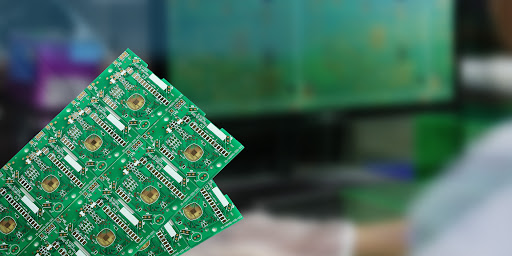

So, you think you have an idea for an innovative new product but you’re not sure how to go about getting it done? You’re not alone – there’s a first time for everything.

You don’t have to be an engineer to develop a new product. With recent innovations in PCB manufacturing, virtually everyone can become an inventory. Whether you’re an amateur inventor, an entrepreneur, or a designer for a startup, here’s a guide to getting your first PCB prototype manufactured.

Plan a Budget

Every project should start with a budget. PCB designs can have virtually infinite configurations and components, so your design can go from affordable to extravagant in no time. Determine your budget in advance so that you can stay on track with your design in your target price range.

For beginners, the cost of education materials and design software should be built in. It’s also smart to include a budget range, so you’re prepared if costs come in a little higher than you anticipate or you need to revise your design to address an error.

Select Core Components

The first step of prototyping is determining what electronic components you will need for your PCB design’s target price and function. These may include connectors, sensors, displays, and microchips.

You can source components with a manufacturing partner or source them on your own. Using a manufacturer will help you eliminate some of the costs and hassle, however.

Create a Schematic

Schematics are vital to diagramming your prototype and the components. Modern PCB design software offers a variety of helpful tools, such as intuitive features and complex, 3D applications to design your prototype to your specifications and skill level.

Beginners should start with simpler designs to get a firm grasp of the basic concepts of circuitry. As you design and learn, you can take on more complicated projects with complex layers and components.

Plan a Master List of Components and Materials

Your schematic can guide you in devising a master list of the components and materials you’ll need for your PCB. Also known as a Bill of Materials (BOM), the master list allows you to itemize all your raw materials and components and cut costs or upgrades where possible.

Fortunately, many PCB design software solutions create BOMs automatically based on your schematic. Some even offer alternatives to components or materials for lower costs or better performance.

Refine Your Design and Layout

At this point, you know that your PCB design is functional and within budget, so it’s time to refine. You can experiment with adjusting aspects like the weight distribution, layout, spacing, heat dispersion, components, or trace angles. New materials are always hitting the market, offering solutions for better temperature control, flexibility, or smaller size.

As you experiment, save different versions of your PCB design. When you’re finished, you can compare different versions to see which is the best fit for your Polycarbonate Overlays prototype, according to your desired capabilities and budget.

Test Your Prototype with Software Simulation

Modern PCB software can run computer simulations to ensure your design functions flawlessly. You can wait until you’re finished refining the design to run simulations, or perform them throughout the process to test different changes. Finding errors early in the process will save you time and effort in finding the source and developing alternative solutions.

Many software solutions offer additional guidance, such as possible reasons for error codes and suggestions for corrections. Once you can perform a flawless simulation, you’ll know you have a mathematically sound design that’s ready for manufacturing.

Save a Gerber File

In the PCB industry, Gerber files are used as the standard for PCB designers and manufacturers. When you have a solid PCB design, you can save it as a Gerber file for quick and simple delivery to the manufacturer for production.

Build a Relationship with the PCB Manufacturer

PCB manufacturers often help beginners and amateurs in bringing their dream to reality. Most manufacturers have a team of experienced engineers to help you with questions and concerns, evaluate your design, and suggest different materials, components, or design changes for a small fee.

When you have a sound design and a BOM, you can submit your Gerber files to the manufacturer to begin printing your custom PCB. If you’re printing a high-volume order, you may want to consider a prototype testing to make sure the board performs as intended before moving forward with a large order.

Author Bio: Justin Ou

Justin Ou is one of four Co-founders and Marketing Manager of Gerber Labs, an Orange County based engineering startup that is currently rolling out a platform that makes custom printed circuit boards (PCB’s) accessible to electrical engineering students, hobbyists and small businesses.